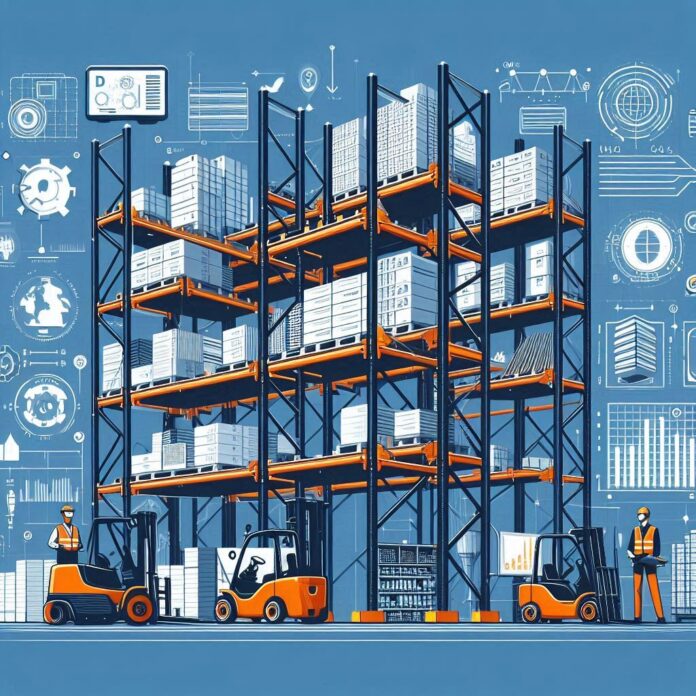

Cantilever racking is a versatile and efficient storage solution that is consistently relied upon across many industries. Its unique design allows for the easy storage of long, bulky items such as timber, pipes and metal sheets. When considering the implementation of cantilever racking, understanding its key elements is crucial. This article will explore six essential components that contribute to an effective cantilever racking design.

Base Structure

The base structure is the foundation of any cantilever racking system, providing the necessary stability and support to hold the weight of the stored items. Typically made from steel, the base must be securely anchored to the floor to prevent any tipping or instability. The size and strength of the base should be proportional to the load it will support to ensure safety and durability.

Upright Columns

Upright columns are vertical supports that determine the height of the cantilever racking system. These columns need to be strong enough to bear considerable weight and durable enough to withstand daily wear and tear. The height of the upright columns should be selected based on the type of materials stored and the available warehouse space. Adjustable columns can offer flexibility, allowing for modifications as storage needs evolve.

Arms

The arms typically extend horizontally from the upright columns and are responsible for holding the stored items. These arms need to be both strong and adjustable to accommodate various load sizes and shapes. The length and spacing of the arms should be carefully planned based on the dimensions and weight of the items being stored. Ideally, the arms should also have a slight upward tilt to prevent items from rolling off.

Bracing

Bracing is another essential component that provides additional support and stability to a cantilever racking system. It typically consists of diagonal and horizontal braces that connect the upright columns. Proper bracing ensures that the structure can handle heavy loads without buckling or swaying. When designing your racking system, it’s important to incorporate adequate bracing to meet safety standards and maintain structural integrity.

Load Capacity

Understanding the load capacity is critical in cantilever racking design. Each component of the racking system, from the base to the arms, must be capable of supporting the intended load. Overloading the system can lead to structural failure and potential hazards, making it essential to calculate the maximum load capacity and adhere to it strictly. Consulting with a structural engineer can help determine the safe load limits for your specific application.

Customisation

Cantilever racking systems can be customised to meet specific storage needs. Whether it’s adjusting the height of the upright columns or the length of the arms, these systems can be tailored to cater to different requirements. This flexibility makes cantilever racking a popular choice for industries with diverse storage needs. When designing a cantilever racking system, think about future scalability and adaptability to ensure the racking can evolve with your business.

Conclusion

Cantilever racking is a highly efficient storage solution that offers numerous benefits when designed correctly. By considering the base structure, upright columns, arms, bracing, load capacity and customisation, you can create a cantilever racking system that maximises storage space, enhances safety and improves operational efficiency.